FOOD SAFETY MANAGEMENTFood Safety Management

commitment to "faithful production" and "customer health," and has established separate, inter-departmental Food Safety Decision-making Teams at both the production side and the channel side. Rigorous measures are implemented to ensure food safety throughout the production cycle, from product development, raw material supply, production processes, finished product quality control, product launch, to after-sale services. By installing a comprehensive management system and procedures, not only do we comply with the latest Act Governing Food Safety and Sanitation; in addition, we also actively promote third-party certified management systems, such as HACCP, ISO 22000, and FSSC 22000, to incorporate the awareness for risk and hazard management into our processes. For instance, in terms of our meat products, we insist on preserving traditional techniques and produce all lard in-house to completely eliminate any possible food safety risk from externally procured oils. Though numerous food safety hazards had occurred in Taiwan in recent years, our efforts have steered Hsin Tung Yang clear of such hazards and allowed us to continuously retain consumers' trust.

Development

Product Development

- Additives that are not critical are eliminated from the formula and we are continuing to work toward Clean Label actions.

- Inspection of quality management system, food safety management system, certification system and applicable food and health laws.

Raw material

Supplier Management, Input Management, Raw Material Inspection

- Raw material is inspected by Quality Assurance laboratory and third-party unit.

- Integrate product traceability with supply chain management; information on raw materials is immediately available upon entering the plant, and non-scheduled visits to suppliers' production plants are carried out.

Production

Processing Control

- HACCP food safety management system is implemented to eliminate risks related to food safety hazards and to ensure product safety and customer health.

- OEM supplier is asked to undergo rigorous assessment mechanism and periodic audits.

Finished products

Finished Product Quality Control

- Finished goods produced by Hsin Tung Yang and OEM goods are inspected and analyzed by the Quality Assurance laboratory and third-party unit.

- Product sampling is conducted on products not made in-house.

Launch

Warehousing, Logistics, Channel Management

- Understanding product movement

- Inspection of specification and quality of suppliers' finished goods and raw materials

- Weekly inventories of in-store products

- Daily inspection of cooked/ready-to-eat products

After-sale service

Customer Communications and Food Safety Crisis Management

- Dedicated customer service hotline

- In case of food safety incident, product in question shall be immediately submitted to inspection and a qualified report shall be issued, or the product shall be discontinued and recalled.

FOOD SAFETY MANAGEMENT FRAMEWORKFood Safety Management Framework

Hsin Tung Yang's food safety management is coordinated by the President, and product quality and food safety issues are discussed through regular monthly Company-wide meetings. Additionally, separate Food Safety Decision-making Teams have been set up both at production side and at our channels, thereby construing a complete food safety management team. The food safety team at the production side is in charge of input, production, and output processes, while the food safety team at the channel side is in charge of managing sources of merchandise, suppliers, product launch and discontinuation, sales, and dining and beverages at our channels. Additionally, the Customer Service Office understands consumers' opinions through the dedicated customer service hotline, 0800-011367, and reflects such opinions to the headquarters, production division and business.

President

President

Production DivisionFood Safety Decision-making Team

In charge of quality control of all factory units, health and sanitation management, ISO, CAS, and HACCP processing management systems and related adjustment and maintenance of their respective validity

Quality assurance and health management personnel

Draft factory health and quality standards and carry out sampling inspection

Procurement

- Sanitation of purchased raw material

Production management

- Sanitation of scheduled production

Supplies

- Raw material storage, sanitation of input warehouse

Shop floor

- Packaging sanitation

Warehousing

- Finished product storage, sanitation of inventory and logistics

Management

- Environmental sanitation at factories

Production Affairs

- Production facilities, water quality maintenance

President

Channel DivisionFood Safety Decision-making Team

Responsible of food health and safety and quality management of all channel business divisions, and adjustment and maintenance of the validity of the Regulations on Good Hygiene Practice for Food (GHP) and Hazard Analysis and Critical Control Point (HACCP)

Food Safety Health Management Center

- Fill out and submit food safety monitoring plan checklist

- Facilitate retail space safety and health management audit

- Assist in audit of suppliers and purchased merchandise

- Implementation and supervision of GHP standard

- Propose, execute and supervise food safety management system

- Other related food safety and health management and employee training

Merchandise

- Supplier management and audit

- Merchandise procurement management

- Merchandise audit

- Voluntary management and traceability

- Management and audit of own-brand retail space

Channels (stores, highway, airport)

- All finished products provided by suppliers

- Merchandise inventory management

- Venue sanitation and safety

Customer Service Office

- Complaints and consumer consultation

The Food Safety Team of Hsin Tung Yang’s Production Division convenes annual review conferences and inspects the implementation status of quality management systems such as HACCP and ISO and quality objectives during monthly meetings. In addition, abnormal incidents and customer complaints are inspected and relevant departments are asked to make improvements, and related laws and standards are also regularly updated. Additionally, food safety management personnel are also arranged to receive internal and external training to ensure that they are aware of the latest food safety technologies and legal information. In 2019, 36 personnel from quality management, production management, and procurement department have participated in related training, and this figure covers 100% of all production lines at Production Division.

| Category | Course/item | Hours | Number of participants |

|---|---|---|---|

| Functional training | 2019 Food Industry Personnel Functional Training and Practicum for Introduction of Planned Audit | 16 | 1 |

| 2019 CAS Enterprise Laboratory Experimental Skills Training Course | 16 | 1 | |

| Food Factory Raw Material Management Practicum | 28 | 2 | |

| Organic Solvent Operations Supervisor Training | 18 | 1 | |

| ISO Articles | A Thorough Study of ISO 22000:2018 | 6 | 1 |

| ISO 22000:2018 Food Safety Management System Training | 12 | 1 | |

| ISO 14001:2015 Environmental Management System - Articles and Internal Auditor Training | 132 | 22 | |

| Regulatory Briefings | 2019 Conference for Promoting Food Company to Retain Product Sourcing Document (Traceability Training) | 3 | 1 |

| 2019 Course and Conference for Food Company Traceability System and Guidance on Applicable Food Safety Laws | 7 | 1 | |

| 2019 Conference for Self-Management from Metallic Food Containers and Packaging Companies | 4 | 2 | |

| 2019 Conference for Promoting Food Production Packaging Material Management and Self-Regulation Enhancements | 8 | 2 | |

| 2019 Skills Testing and Updated Legal Environment Conference | 4 | 1 | |

| Subtotal | 254 | 36 | |

In 2019, a series of courses and training encompassing diverse topics were organized by Hsin Tung Yang to facilitate food safety personnel from various channel units to comprehend related food safety management mechanisms and to understand the latest legal environment.

| Training department | Type of course | Total hours | Number of trainees |

|---|---|---|---|

| Merchandise Division | Food safety monitoring plan, general catering sanitation and hygiene seminar and related legal seminar | 51 | 15 |

| Airport Operations Division | Food sanitation and hygiene seminar, HACCP food safety management system | 307 | 64 |

| Highway Operations Division | Dining and beverage sanitation and hygiene seminar | 62 | 40 |

| Subtotal | 417 | 119 | |

FOOD SAFETY MANAGEMENT SYSTEMFood Safety Management System

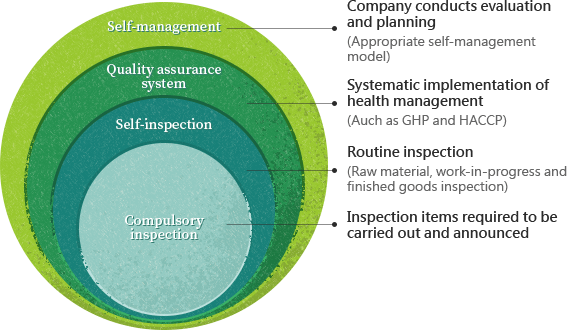

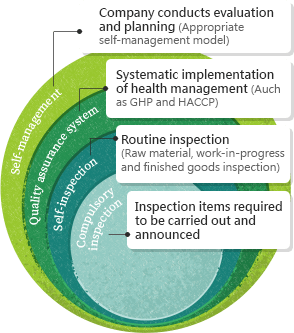

By using food safety management system as a roadmap, Hsin Tung Yang evaluates and analyzes risks in the overall production and sales chain and taken the initiative to create a food safety management system and established "food safety monitoring plan" to ensure the safety and health of our food products. On top of complying with applicable food safety laws, Hsin Tung Yang also actively meets international quality standards and achieves third-party assurance. Take HACCP food safety management system for instance, our Dayuan Plant has already received relevant certification in as early as 2002, before the system was made mandatory by the government. In 2019, we have confirmed Hsin Tung Yang's compliance with both the Act Governing Food Safety and Sanitation and Enforcement Rules of the Act Governing Food Safety and Sanitation, and there has been no record of violation of applicable food safety laws.

- We implement self-management based on the Act Governing Food Safety and

- Hsin Tung Yang adheres to the Regulations on Good Hygiene Practice for Food (GHP), Hazard Analysis and Critical Control Point (HACCP), Regulations of Recall and Destruction for Food and Related Products, and various health standards, restrictive volume standards and related safety and health regulations.

- Setting HACCP as the basis of self-quality assurance system, management is enforced on four aspects including operators, processing grounds, facility health management, and quality assurance system. We systematically plan appropriate measures for the supply chain and have received third-party management system certification, thereby achieving sound food safety management.

- Hsin Tung Yang's Dayuan Plant has received certifications of HACCP food safety management system, ISO 22000 food safety management system, and FSSC 22000 food safety management system and food business health and safety management system. Boundaries of aforementioned certifications cover all product lines for meat and poultry processing, canned pork meat, aquatic produce, pastries, and snacks from Production Division, and ratio of coverage is 92.1%.

- Based on our risk analysis and management principles, Hsin Tung Yang evaluates and implements inspections and other matters that are either on par with or more rigorous than the basic requirements from compulsory inspections based on the characteristics of products sold, quality assurance system, and capacity for carrying out self-inspection. And such inspection results are used to demonstrate the effectiveness of our quality management measures.

- Samples are taken from Hsin Tung Yang's major products, and submitted to a third-party assurance unit for inspection on an annual basis.

- Hsin Tung Yang's quality assurance personnel will conduct sampling inspections based on the criteria and number of samples stipulated in the quality management programs for each product.

- Hsin Tung Yang carries out compulsory inspections for items required by the law; for instance, annual sampling inspection plan is established for raw meat materials for processed meat products, egg products, and baking products. Reasonable inspection items are carried out after evaluations, and samples are also submitted to third-party assurance unit for inspection on a quarterly basis.

- We implement self-management based on the Act Governing Food Safety and

- Hsin Tung Yang adheres to the Regulations on Good Hygiene Practice for Food (GHP), Hazard Analysis and Critical Control Point (HACCP), Regulations of Recall and Destruction for Food and Related Products, and various health standards, restrictive volume standards and related safety and health regulations.

- Setting HACCP as the basis of self-quality assurance system, management is enforced on four aspects including operators, processing grounds, facility health management, and quality assurance system. We systematically plan appropriate measures for the supply chain and have received third-party management system certification, thereby achieving sound food safety management.

- Hsin Tung Yang's Dayuan Plant has received certifications of HACCP food safety management system, ISO 22000 food safety management system, and FSSC 22000 food safety management system and food business health and safety management system. Boundaries of aforementioned certifications cover all product lines for meat and poultry processing, canned pork meat, aquatic produce, pastries, and snacks from Production Division, and ratio of coverage is 92.1%.

- Based on our risk analysis and management principles, Hsin Tung Yang evaluates and implements inspections and other matters that are either on par with or more rigorous than the basic requirements from compulsory inspections based on the characteristics of products sold, quality assurance system, and capacity for carrying out self-inspection. And such inspection results are used to demonstrate the effectiveness of our quality management measures.

- Samples are taken from Hsin Tung Yang's major products, and submitted to a third-party assurance unit for inspection on an annual basis.

- Hsin Tung Yang's quality assurance personnel will conduct sampling inspections based on the criteria and number of samples stipulated in the quality management programs for each product.

- Hsin Tung Yang carries out compulsory inspections for items required by the law; for instance, annual sampling inspection plan is established for raw meat materials for processed meat products, egg products, and baking products. Reasonable inspection items are carried out after evaluations, and samples are also submitted to third-party assurance unit for inspection on a quarterly basis.

To continuously enhance our food health, safety and quality, Hsin Tung yang implements active measures targeting operators, processing grounds, facility health management and quality assurance system to safeguard the health of our consumers. The boundaries of impact from related implementations in 2019 covered meat and poultry processing, canned pork meat, aquatic produce, pastries, and snacks and traditional zongzi, or 100% of all in-house products and OEM products at Hsin Tung Yang's Dayuan Plant.

| Food Health, Safety, and Quality Improvement Programs in 2019 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Category | Program | ||||||||||||

| Quality assurance system | Quality Enhancement Programs achieved in 2019:

Due to increased production volume, August 2019 had 29 abnormalities, exceeding target by 1 incident. In terms of management mechanism over abnormalities detected during quality inspection, Hsin Tung Yang analyzes the causes through "quality abnormality reporting form" and drafts improvement measures to prevent further occurrence. | ||||||||||||

| Facility Management |

| ||||||||||||

| Processing Grounds |

| ||||||||||||

| Operators |

| ||||||||||||

QUALITY MANAGEMENT AND INSPECTIONQuality Management and Inspection

To ensure that Hsin Tung Yang's production quality can meet customers' expectations for taste while complying with relevant safety and health standards, we carry out and maintain our quality system while strengthening both "laboratory inspection" and "food retail management" at production and sales end.

STRENGTHEN LABORATORY TESTINGStrengthening Laboratory Inspection

From raw material input to product output, all Hsin Tung Yang products are required to go through inspections from our Quality Assurance lab and an external third-party unit. Relevant inspections are carried out via standardized procedures (national standards or methods announced by the Taiwan Food and Drug Administration) and utilize standardized equipment. In terms of legally required compulsory inspections, annual sampling inspection plans are established, and samples are also submitted to third-party assurance unit for inspection on a quarterly basis. In addition, self-inspection is also reinforced; for major products and festive products, samples are submitted to third-party assurance unit for inspection in each year, while quality assurance personnel will also conduct sampling inspections based on the criteria and number of samples stipulated in the quality management programs for each product.

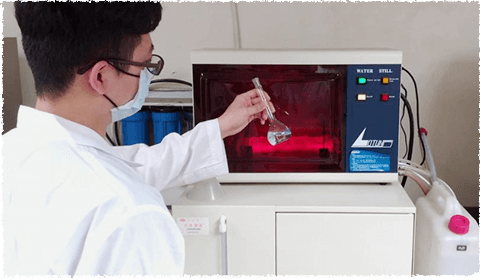

Currently, Hsin Tung Yang has already established a food safety laboratory at Dayuan Plant in compliance with applicable laws, and the facility can carry out general chemical analysis, tests for microorganisms, and rapidly screen for veterinary drug residues. To enhance the capacity for inspection analysis, 3M Molecular Detection System (MDS) was installed in 2019 to conduct rapid and specific detection of Listeria and Salmonella, allowing for supervision and control over all in-house production at Dayuan Plant.

The human resources used to maintain food safety at Dayuan Plant, and the inspection expenses and facility maintenance at the food safety laboratory and third-party inspection expenses in 2019 amounted to nearly NT$5.48 million, accounting for 0.54% of the revenues from Dayuan Plant. Our future target objective is for the food safety laboratory to be certified.

Hsin Tung Yang Product Inspection Items

| Hsin Tung Yang Product Inspection Items-Self-inspection items at Hsin Tung Yang laboratory |

|---|

|

| Hsin Tung Yang Product Inspection Items-Third-party inspection items |

|---|

|

| Hsin Tung Yang's Own Laboratory Inspection Results in 2019 | |||

|---|---|---|---|

| Category | Inspection Item | Sample size | Ratio of certified products |

| Raw material | Veterinary drug residues | 120 items | 100% |

| Microorganisms | 1866 items | 98.55% | |

| General chemicals | 2669 items | 98.80% | |

| Meat products | Microorganism | 6607 items | 99.88% |

| General chemicals | 6776 items | 98.86% | |

| Pastries (including festive products) | Microorganism | 451 items | 99.78% |

| General chemicals | 1139 items | 98.33% | |

| Third-party Inspection Results in 2019 | |||

|---|---|---|---|

| Category | Inspection Item | Sample size | Ratio of certified products |

| Raw material | Veterinary drug residues, heavy metals, pesticide residues, microorganisms and aflatoxin | 50 items | 100% |

| Finished food product (including OEM products) | Veterinary drug residues, heavy metals, pesticide residues, microorganisms and aflatoxin, plasticizers, preservatives, coloring, sweeteners etc. | 180 items | 100% |

| Mai's HK Roast Food lunch boxes and ingredients | Microorganisms, pesticide residues etc. | 10 items | 100% |

STRENGTHEN FOOD SALES MANAGEMENTStrengthening Channel Food Retail Management

From inspection before product launch to sales management of in-store products, a comprehensive merchandise management system, one that is integrated with supply chain management, has been set up at our channels. The smooth, systematic operations at our headquarters, store personnel, and suppliers are coordinated to ensure a satisfactory shopping environment for our customers. Verification, inventories, and validity inspection of in-store merchandise is conducted on a weekly basis, in which merchandise checklist and merchandise review form are filled and documented.

We pay particular attention to the quality and cooked meals served at highway service areas and airport shops. Besides implementing the "merchandise retail SOP" and "Detailed Regulations on Using Oils and Seasoning" at all food and beverage counters, all cooked meals produced by Hsin Tung Yang have also passed inspections from third-party units. Additionally, relevant protective measures and cooked meal quality management procedures are also established and enacted at at the same time. Hsin Tung Yang has created the cooked food health inspection table for daily self-inspections. Retail of any food or beverage can only be made after review and approval from our "food and beverage review team," comprised of our food professional technologists, cooked food developers, and food and beverage counter developers. An independent third-party unit is also commissioned to conduct sampling inspection on a monthly basis.

Self-Management of Quality and Finished Goods of Cooked Foods

Source

- Raw material purchase, input inspection management, supplier evaluation management

Storage

- Implement first-in, first-out (FIFO), and separate raw and cooked foods

- Conduct three temperature checks and patrols daily at refrigerators and freezers and record humidity of dried goods warehouse

Manufacturing

- Implement SOP for personnel health and hygiene and cleanliness of equipment and environment

- Inspect quality of frying oil twice daily, and adopt more rigorous oil replacement standards than legal requirements (22%)

- Plan processing flow to prevent cross-contamination

- Monthly and quarterly sampling inspection

Retail

- Cooked foods (lunch boxes) are sold on the day they are made

- Temperatures of freezers and refrigerators are checked three times daily

- Unpackaged cooked foods are covered to prevent dust and respiratory droplets

- Utentils undergo inspections for residues of carbohydrates, fats, and dishwashing liquids from professional inspection agency on a monthly basis

Disposal

- Documented based on established processes, and leftover foods are recycled

Daily

- Establish cooked food health inspection table for daily self-inspections.

- Frequency of sampling inspection is increased for merchandise with higher risks to protect consumers' health.

- Self-inspection of fresh vegetables/fruits from time to time.

Immediately

- In case of likely food safety incident, Hsin Tung Yang will immediately inspect the safety of related products, and to ensure consumers' health, the product may be discontinued when necessary.

- Merchandise in question will be immediately submitted for inspection, and relevant suppliers will be requested to conduct inspections at the same time.

Subsequently

- If the merchandise passes relevant inspections, it will be re-launched and an announcement regarding its safety will be made.

- Information on related food safety concern will be documented and remedial/protective measures will be developed to prevent recurrence.

Hsin Tung Yang is Always

Committed to Food Safety