SUPPLY CHAIN MANAGEMENTSupply Chain Management

Hsin Tung Yang has established a comprehensive food value chain, and every supplier and vendor is a collective management partner who helps us to achieve co-prosperity. Through rigorous management measures, Hsin Tung Yang ensures food safety and achieves sustainability, and together, we are committed to enhancing brand image and product and service quality, and for providing the best customer experiences.

TYPE OF VENDORTypes of Supplier

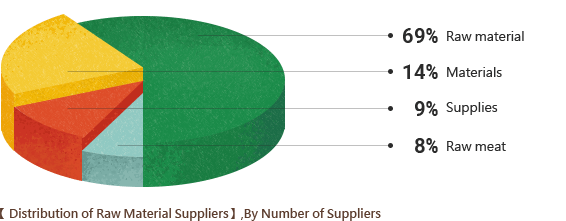

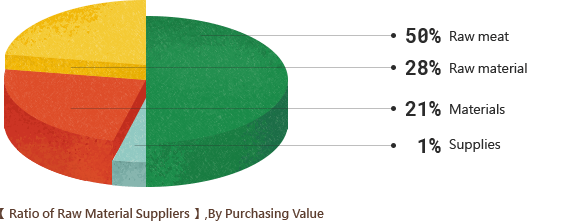

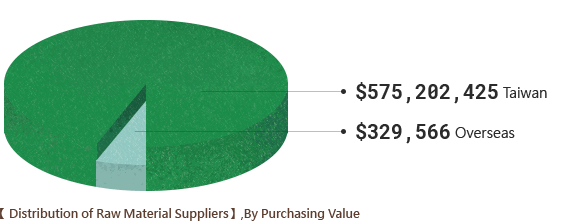

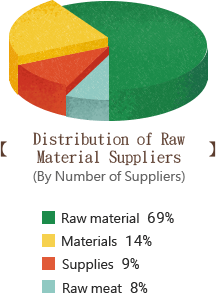

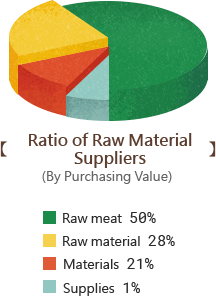

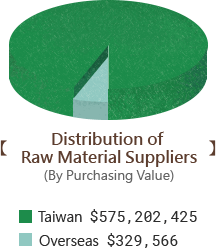

Suppliers of Hsin Tung Yang's own brands include raw material suppliers and OEM suppliers, while most of the suppliers for our stores are merchandise suppliers, and external vendors for highway service areas. Raw material suppliers include raw meat, ingredients, materials, and supplies, and we had 224 of such suppliers in 2019. In particular, 223 of which were Taiwanese manufacturers and trading companies, and only 1 was a foreign enterprise (a German importer of spices). The local raw material procurement ratio at Dayuan Plant has reached 99.9%.

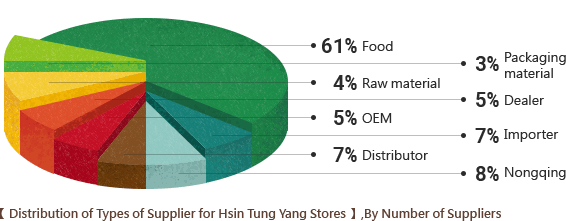

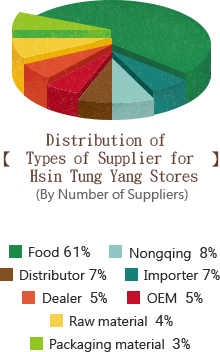

In terms of OEM, Hsin Tung Yang's Dayuan Plant has had 10 OEM suppliers in 2019, and all of which were food processing companies from Taiwan. We have had 524 suppliers to our shops; most of which were suppliers for food, agricultural produce, raw materials, importers, logistics, and distributors.

SUSTAINABLE PURCHASINGSustainable Procurement

Hsin Tung Yang purchases environmentally-friendly and sustainable raw materials to ensure that environmental impacts are mitigated while being committed to the quality of products and services. Additionally, we also support suppliers of green products to promote sustainable transformation of the industry chain.

Roundtable on Sustainable Palm Oil

Starting in 2019, Hsin Tung Yang began to use oil products certified by the Roundtable on Sustainable Palm Oil (RSPO), an international product responsibility standard, as the raw materials for fruit fillings in pastries. RSPO certified products need to meet 8 principles and 144 indicators across 39 categories in order to ensure that legal compliance, information transparency, local environmental protection, biodiversity, and community and farmers' rights are all protected during palm production processes.

Statistics on RSPO Purchases

| Procurement amount (NTD) | Ratio | |

|---|---|---|

| RSPO certified oils | 4134,976 | 14.29% |

| Total oil purchases | 28,944,637 | 100% |

Colorful Box Printing from Soy Ink

Starting in 2004, to mitigate environmental impacts and to promote environmental protection, all of the color ink used to print Hsin Tung Yang's colored boxes has been soy-based ink in place of petroleum-based ink. The number of colored boxes printed via soy-based ink in 2019 has been 2,963,057 boxes, and related procurement has exceeded NT$34.30 million.

Carbon Footprint Products

In response of sustainable consumption practices, Hsin Tung Yang prioritizes procurement of carbon footprint certified products for our highway service areas and airport shops. Carbon footprint products purchased in 2019 included FIN Healthy-Support Drink, Coca-Cola, Taishan Pure Water, HeySong Sarsaparilla, HeySong Camellia Green Tea, Minute Maid Aloe & White Grape and more. Total procurement was approximately NT$4.7 million, and with the exception of Taisun Pure Water, which is sold exclusively at highway and bus terminal, all certified products are sold in all Hsin Tung Yang channels throughout Taiwan.

Green Mark Certified Cardbord Boxes

Hsin Tung Yang collaborates with suppliers who have achieved the government's Green Mark designation in terms of cardboard box procurement in order to achieve circular economy and to reduce deforestation. We only use cardboard boxes made from recycled papers, and total cardboard box procurement in 2019 had been 842,492 boxes, or NT$7.81 million.

Traceable Agricultural Products

To promote transparency in the agricultural product supply chain and local agricultural development, Hsin Tung Yang has also actively purchased products with Traceable Agricultural Products (TAP) certification on top of establishing the product traceability system. Procurement of TAP products has exceeded NT$7 million in each year over the past three years.

Hsin Tung Yang's Total TAP Procurement Over the Past Three Years

| 2017 | 2018 | 2019 | |

|---|---|---|---|

| Procurement (in kg) | 33,778 | 44,600 | 38,971 |

| Procurement amount (NTD) | 7,205,949 | 9,033,818 | 7,990,549 |

PRODUCT SUPPLIER MANAGEMENTProduct Supplier Management

Suppliers for Hsin Tung Yang's branded and in-store products include raw material suppliers, OEM suppliers, store merchandise suppliers. Suppliers are managed in line with "Supplier Management Procedures" to ensure product quality and compliance with food safety and health laws, thereby protecting brand reputation and protecting the rights and interests of consumers.

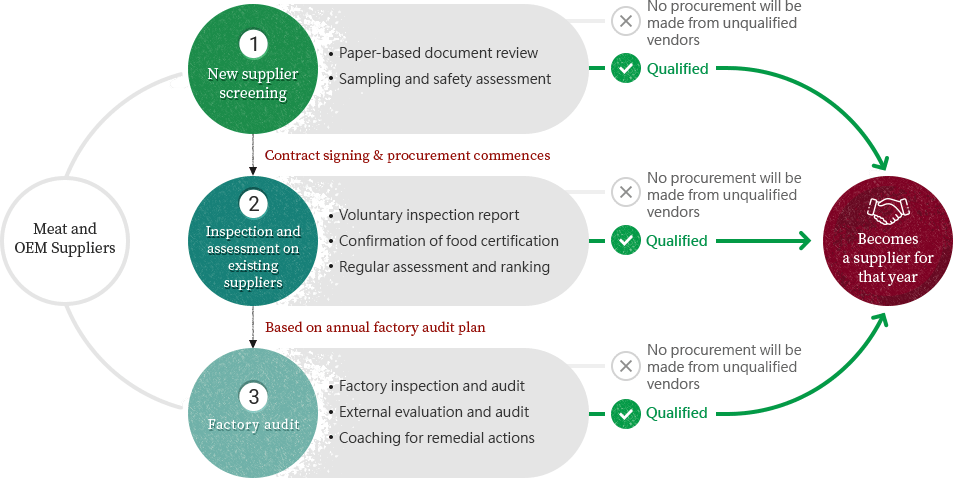

Step1. New Supplier Screening

Hsin Tung Yang adopts the following processes to manage new supplier screening:

Paper-based document: confirmation of basic information such as vendor and factory registration, and meat suppliers need to be qualified butchers approved by competent authority and to pass butchery hygiene and sanitation inspection. Food suppliers need to be registered food companies.

Factory inspection: Quality Assurance unit will conduct onsite inspection to further understand the suppliers' product quality, production processes and technologies, and services, and to confirm that the suppliers are actively managing their environmental impacts.

Sampling and safety assessment: samples would be tested by the R&D unit for evaluation of safety and characteristics. After confirming its safety, our design unit, production unit, or R&D unit will also determine its qualification.

Supplier evaluation: After compiling the aforementioned information, the suppliers would be comprehensively evaluated on factors including paper-based review, quality control, and service quality based on our "Supplier Review Table". Raw material and merchandise suppliers who achieve 70 points total, and OEM suppliers who achieve 80 points or more, can become qualified Hsin Tung Yang suppliers.

Step2. Supplier Assessment and Ranking

Food certification and voluntary inspection report

To ensure the quality and safety of raw materials, we require suppliers to enclose relevant voluntary inspection reports during product delivery. Examples of requirements for various products are as follows:

| Locally produced pork and chicken | Livestock butchery inspection records from the Bureau of Animal and Plant Health Inspection and Quarantine, council of Agriculture, Executive Yuan and proof of quaratine shall be enclosed |

| Imported beef | Complete information on the permit for importing food and related products and imported animal and plant quarantine certificate shall be enclosed |

| Internal packaging materials | Material inspection and migration test report shall be enclosed, and related document shall be provided on an annual basis. |

| General merchandise | Shall comply with regulations from the Commodity Labeling Act and Act Governing Food Safety and Sanitation. |

To ensure that raw material and OEM products from suppliers can meet Hsin Tung Yang's quality, quantity and delivery standards, we regularly score our suppliers with the following criteria: product quality standard, timeliness of delivery, and stability of supply. The following are frequency of assessment, ranking, and incentive/disincentive methods for various suppliers:

Assessment and Ranking of Raw Material Suppliers

Hsin Tung Yang scores and ranks raw material suppliers in every two months. Suppliers are classified into five ranks and corresponding measures would be taken based on their total scores. The number of suppliers being assessed has continued to increase over the past three years. In 2019, 224 suppliers were assessed, accounting for 100% of all raw material suppliers. The following table indicates assessment results in recent years; the ratio of suppliers who achieved A ranking in 2019 has been 97.8%

| 2019 Raw Material Supplier Assessment Results | ||

| Number of suppliers Ranking | 2019 | Reward/disincentive method |

| AA | 122 |

|

| A | 97 |

|

| B | 5 |

|

| C | 0 |

|

| D | 0 |

|

| Number of suppliers assessed | 224 | - |

Assessment and Ranking of OEM Suppliers

OEM suppliers of Dayuan Plant would be scored and ranked once every two months. Evaluation criteria include: product quality standards, timeliness of delivery, and stability of supply. Suppliers would be divided into five ranks, and corresponding measures would be adopted based on their total scores. In 2019, 10 suppliers were assessed, accounting for 100% of all factory OEM suppliers. The following table indicates assessment results in recent years; the ratio of suppliers who achieved A ranking in 2019 has been 100%.

| 2019 OEM Supplier Assessment Results | ||

| Ranking | 2019 | Reward/disincentive method |

| A | 0 |

|

| B | 10 |

|

| C | 0 |

|

| D | 0 |

|

| E | 0 |

|

| Number of suppliers assessed | 10 | - |

Step3. Factory Visit & Audit

Hsin Tung Yang establishes annual audit (factory inspection) plan, and the list of suppliers to be audited is determined based on factors that include annual transaction volume, product significance, customer complaints, and special circumstances. The types of factory audits include: factory certification, raw material management, processing and finished goods management, factory quality system, and onsite personnel and environmental inspection and more. The purpose of such audits is to understand product quality, production technologies, and to ensure food safety.

Supplier Coaching and Improvements

For suppliers with quality concerns, our Quality Assurance unit will also participate in the factory inspection/audit and to propose a "Supplier Audit Report" (including supplier deficiencies and supplier's response and proposed improvements) for deficiencies found during our onsite inspections. Hsin Tung Yang will work with the supplier to find underlying reasons and guide the supplier through the "supplier deficiencies and supplier's response" form to make necessary improvements within a given deadline. Additionally, unqualified suppliers may be replaced. Audit results will also be provided to procurement unit as references for continued partnership.

Raw material Factory Inspection and Audit

We planned and actually carried out the audit for 24 raw material suppliers in 2019, accounting for 17.9% of all suppliers whose transaction volume reached NT$200,000 or above. For 2020, we plan to audit (or visit the factories of) an average of 2 suppliers in each month, and are expected to visit 24 suppliers throughout the year.

| Raw Material Suppliers Audited/Inspected For the Past Three Years | |||

| Year | 2017 | 2018 | 2019 |

| Number of transacting suppliers (NT$200,000 or above) | 121 | 131 | 134 |

| Actual number of suppliers audited/inspected | 23 | 33 | 24 |

| Number of qualified suppliers | 21 | 33 | 21 |

CHANNEL COLLABORATOR MANAGEMENTChannel Contractor Management

Hsin Tung Yang views all contractors across all highway and airport channels as our management partners toward co-prosperity, and we are mutually dedicated to enhancing brand image and service quality via coaching and management at each stage along the way.

Preemptive managemen

Inspection over qualification

Contract and commitment

Educational training

Day-to-day operational audit

Service quality

Management performance

Operational audit

Retail space evaluation system

Daily operations

Food safety evaluation

Business growth

Step1. Preemptive Management

To ensure customer safety, Hsin Tung Yang's Business Development Division at our headquarters will confirm product-related certificates or approved inspections for vendors who wish to collaborate with us. In terms of contract agreements, our court-notarized agreements are based on relevant procedures enacted by government agencies including the Freeway Bureau, MOTC, and we require vendors to strictly abide by contents of the agreements. In case the contractor experiences management issues or commits a major contract violation during the operating period, as a good administrator, Hsin Tung Yang will assist the contractor to retreat from the service area operations based on contract terms and on a principle of fairness and integrity. before the contracted vendor enters the service area, our Highway Service Area Division will organize internal educational training to ensure the vendor's understanding of relevant regulations and service needs.

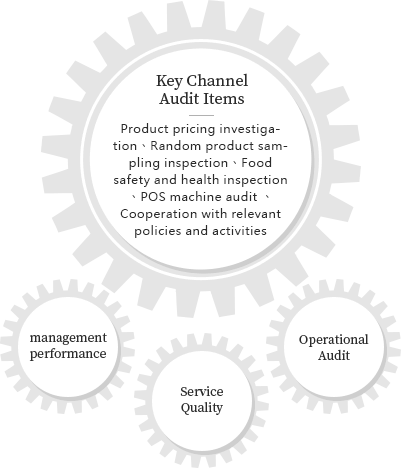

Step2. Day-to-Day Operations Audit

Hsin Tung Yang has established the "Retail Space Management Regulation" that specifies the principles of "personnel management, product management, sales management, and venue management" for retail space, and disincentive measures are stipulated for violations. The audit mechanism covers three major aspects, and responsible units include service area managers, on-duty supervisors, Audit Office at headquarters, Customer Satisfaction Team, Highway Service Area Division, and the Freeway Bureau, MOTC. The service quality, management performance, and operational quality of contractors are confirmed through various investigation methods ranging from regular reviews, audits, to mystery shoppers.

Moreover, Hsin Tung Yang also confirms the cleanliness, sanitation, and service quality of the retail space via periodic scoring systems. Scoring items include the cleanliness and sanitation of personnel, counter area and space, and equipment and facilities, and deficiencies found are tracked for improvement progress. Scoring results are compiled and submitted to the headquarters for inspection and documentation on a monthly basis.

| 2019 Highway Service Area Retail Space Scoring Results (Average Results of Monthly Scores from Jan to Dec) | ||||||||

| Score | Guanxi Service Area | Xihu Service Area | Qingshui Service Area | Nantou Service Area | ||||

| Number of retail counters | Ratio | Number of retail counters | Ratio | Number of retail counters | Ratio | Number of retail counters | Ratio | |

| Outstanding | 4 | 23% | 7 | 37% | 13 | 39% | 4 | 29% |

| Good | 6 | 33% | 3 | 13% | 5 | 16% | 6 | 38% |

| Qualified | 8 | 45% | 10 | 50% | 15 | 45% | 5 | 32% |

| Total | 18 | 100% | 20 | 100% | 33 | 100% | 15 | 100% |

2019 Highway Service Area Retail Space Scoring Results

(Average Results of Monthly Scores from Jan to Dec)

| Score | Guanxi Service Area | |

| Number of retail counters | Ratio | |

| Outstanding | 4 | 23% |

| Good | 6 | 33% |

| Qualified | 8 | 45% |

| Total | 18 | 100% |

| Score | Qingshui Service Area | |

| Number of retail counters | Ratio | |

| Outstanding | 13 | 39% |

| Good | 5 | 16% |

| Qualified | 15 | 45% |

| Total | 33 | 100% |

| Score | Nantou Service Area | |

| Number of retail counters | Ratio | |

| Outstanding | 4 | 29% |

| Good | 6 | 38% |

| Qualified | 5 | 32% |

| Total | 15 | 100% |

| Score | Xihu Service Area | |

| Number of retail counters | Ratio | |

| Outstanding | 7 | 37% |

| Good | 3 | 13% |

| Qualified | 10 | 50% |

| Total | 20 | 100% |

Step3. Contractors' Retail Space Evaluation and Incentives

To encourage contractors to enhance their service quality and to ensure food safety, Hsin Tung Yang has been implementing the "contractors' retail space evaluation system" in as early as 2009. Relative weights are given for criteria that include "daily operations," "food safety evaluation," and "percentage of revenue from retail space," and contractors with scores above 70 points are qualified, while "good" indicates a contractor that scores more than 80%, and "outstanding" contractors are those who score above 85 points. Seals are placed at obvious locations at the retail space, thereby enhancing contractors' sense of accomplishment and pride, and high-performing contractors will also be prioritized in future contract renewals.

| Evaluation items | Evaluation unit | Evaluation method | Weight | Evaluation results |

| Daily operations | On-duty supervisors | Based on the table of retail space evaluation | 30% | Qualified" for 70 points or above, Good" for 80 points or above, and Outstanding" for 85 points or above |

| Food safety evaluation | Impartial third-party | From time to time in each month | 40% | |

| Percentage of revenue growth from retail space | Service Area managers | Compared with sales revenues from the previous year | 30% |

SUSTAINABLE SUPPLY CHAINSustainable Supply Chain

ESG Management

To encourage raw material suppliers to join us in sustainable development and clean production processes, Hsin Tung Yang has incorporated ESG criteria in the criteria for "Supplier Review Table," where such criteria account for 35% weight. Suppliers that meet three or more of the following criteria will be deemed as "green suppliers," and procurement from such suppliers would be prioritized. Between 2017 to 2019, all of Hsin Tung Yang's new suppliers have passed the ESG screening process.

- External packaging adopts renewable materials or are clean, complete, and meet relevant requirements

- Received sustainability certificates (e.g. Organic TAP, CAS, GMP and etc.)

- Third-party food safety audit report or HACCP plan

- Equipped with environmental protection processes and surveillance measures

- No use of child labor

| 2017 | 2018 | 2019 | |

| Number of new suppliers | 11 | 23 | 17 |

| Number of suppliers screened using ESG standards | 11 | 23 | 17 |

| Ratio of new suppliers that passed the ESG screening standards | 100% | 100% | 100% |

| Number of physically inspected suppliers | 9 | 9 | 2 |

Supplier Certification and Advocacy for Sustainability

On top of ESG screening, signing the statement of sustainability, and environmental impact risk assessment, Hsin Tung Yang also conducts general inspections overall raw material suppliers in each year. We encourage our suppliers to receive international certifications on food safety and environmental sustainability, such as ISO, HACCP, product traceability system, organic certifications, and the Green Mark.

| Certification standards | Number of raw material suppliers | Percentage |

| HACCP certification | 73 | 54% |

| ISO 22000 certification | 65 | 49% |

| Hsin Tung Yang's green suppliers | 99 | 74% |

| Number of all transacting suppliers※ | 134 | 100% |

※ Cumulative transactions reach NT$200,000 in a year

Additionally, to promote a green supply chain, Hsin Tung Yang organized the Supplier Sustainability Forum in 2017, where we joined Foundation of Taiwan Industry Service in discussing and sharing our experiences related to the theme, "Responding to International Sustainability Trends and Green Factory Promotional Strategies". The forum was participated by 32 companies. Hsin Tung Yang will continue to advocate to and to interact with suppliers based on our commitment to achieve sustainability, and we aspire to join all vendors throughout our industry chain to build a green food value chain.

Environmental Impact Risk Assessment

To understand the risks of environmental impact in our supply chain, Hsin Tung Yang has carried out the identification of non-manufacturing environmental factors based on 49 of our existing raw material suppliers. Eight high-risk suppliers have been identified, and relevant action plans have been drafted. The procurement unit will audit the high-risk suppliers, and 50% of such audits are expected to be completed in 2020.

Identifying types of material, energy, and environmental impact

Assessments based on environmental impacts and levels of impact while taking legal regulations into consideration

Risk/opportunity suppliers are identified

Establish and implement action plans

【 Suppliers' Environmental Risk Management Procedures 】

Suppliers' Statement of Environmental Sustainability

Hsin Tung Yang has established sustainable development terms and invited our raw material suppliers to sign and to conform to such terms. Besides specifying regulations for products' conformity to the Act Governing Food Safety and Sanitation, our procurement contracts also stipulate the following: To promote conservation of the Earth's environment and reduce impacts on the ecosystem as well as an awareness for sustainable consumption and recycling, the supplier shall comply with applicable laws and to promote relevant environmental protection awareness including energy conservation, carbon reduction, and to protect the planet. Starting from 2019, Hsin Tung Yang has signed the aforementioned statement with 165 raw material suppliers, which accounts for nearly 74% of all raw material suppliers.

Persistence in Rigorous Selection Process